Ströter + BEGE = Innovation

Ströter and BEGE are known for the development and innovation of reliable drive solutions.

Ströter Development & Innovation

As a result of the acquisition of Ströter Antriebstechnik by BEGE, we have been a manufacturer of Ströter drive components since 2015. Because we not only supply but also produce Ströter products, we are more flexible in terms of delivery times and in terms of adjustments to the standard version and we can implement further developments in the program.

Ströter innovation

Innovation has always played a very important role at Ströter. They have been ahead of their time since the moment they were founded.

For example, Ströter developed the AM variable-speed drive, the precursor of the frequency converter. This made it possible to mechanically regulate the speed of the drive by varying the gear ratio.

In addition, the company focused on energy-efficient solutions as early as the 1980s and 1990s, even though the market wasn’t ready for this at the time.

Symbiosis of Ströter and BEGE

The close relationship between Ströter and BEGE led to collaboration with mutual benefits in the 1960s. While Ströter focused on the production of helical bevel gear units, BEGE focused on helical gear units. Both companies sold each other’s products in order to always be able to offer machine builders the right solutions. Today, all production activity has been integrated into BEGE and we supply the entire range of Ströter drive components for a variety of applications.

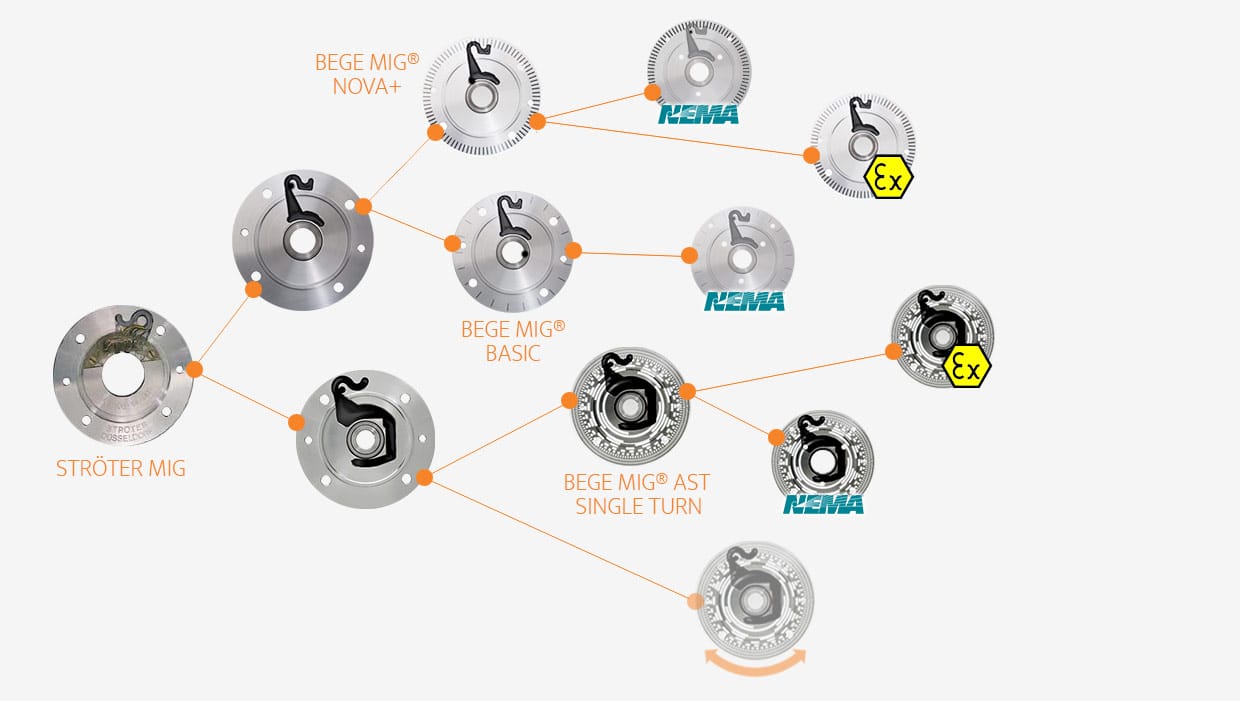

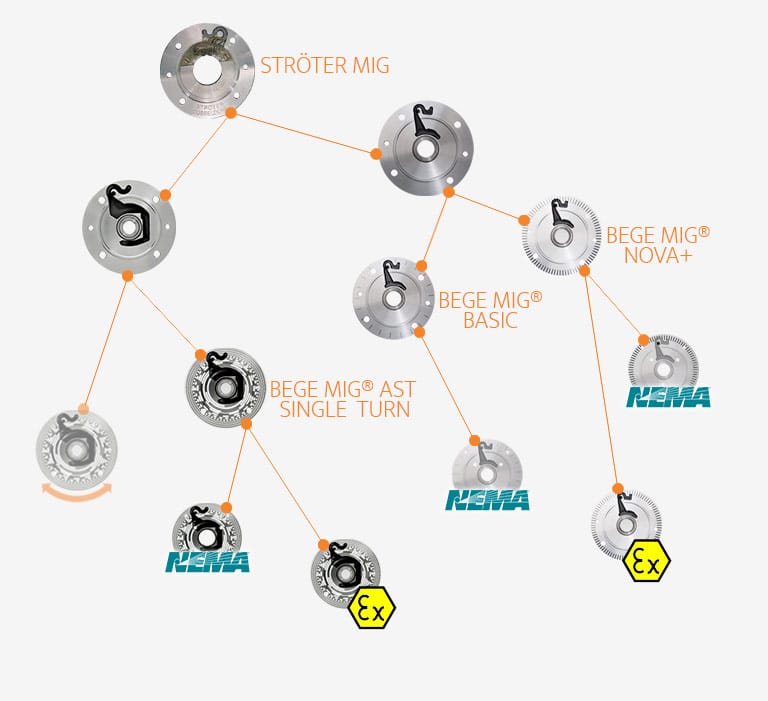

We’ve continued the innovation trend even after the acquisition of Ströter in 2015. Among other advances, this has included further development of the flange encoder. Thanks to continuous optimization, the MIG has become even more compact and is now available in three different variants.

Development of Ströter MIG encoder

Our engineers work on innovative solutions to optimize our encoders. With our own engineering lab, test facilities and workplace, we design and develop the next generation MIG encoders.

Revolutionary and Robust

What makes the BEGE MIG® encoder innovative is the use of a flange in combination with a synthetic ring magnet. An encoder usually has a ferrite ring magnet, a ceramic material that is brittle and therefore fragile. In contrast to other types of encoders and flange encoders, the BEGE MIG has a robust ring magnet made of vulcanized plastic. This encoder is easy to mount and will not break during installation or during the process, thanks to the BEGE MIG’s shock resistance.

The BEGE MIG encoder has a high IP rating. It is IP67 certified, which means it is absolutely dust-proof and completely waterproof. Because the MIG encoder is integrated between the gearbox and the motor, dirt cannot accumulate. This encoder is therefore trouble-free, dustproof and waterproof; which are essential properties for cleaning in hygienic environments.

Compact and Accurate

Standard encoders are very precise but vulnerable in an industrial environment, since they cannot be integrated between the motor and the gearbox. Existing encoders that are suitable for intermediate installation do not offer high precision.

The BEGE MIG encoder is compact because it can be installed as a flange in standard IEC sizes between the motor and the gearbox. It combines flexibility with high precision. The BEGE MIG can generate up to 2048 pulses, while standard flange encoders usually top out at 50 pulses. This makes the BEGE encoder forty times as precise. Among other benefits, this leads to more precise dosing thanks to a more exact drive adjustment. The MIG encoder thus combines the best of both types of encoder.

View the comparison table to see the differences between the various MIG encoders.

Innovative Drive Partner

As a reliable drive partner for the industry, we offer advanced concepts and products in the field of drive engineering to meet today’s major challenges.

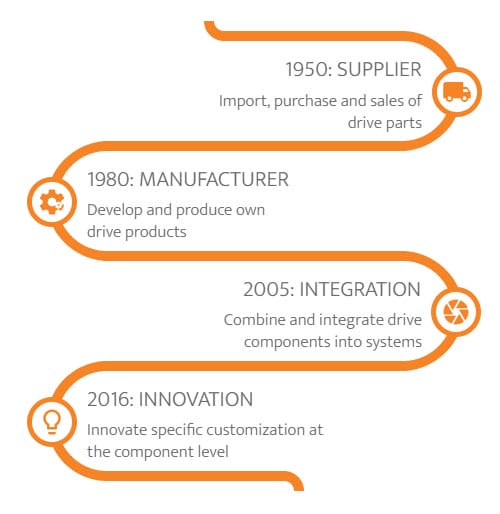

Innovation at a Component Level

With years of experience in power transmission, BEGE not only supplies the parts – whether from Ströter or others – but also offers innovative customized solutions, tailored to sector- or customer-specific requirements. Whether it’s a small, compact machine or an extensive, complicated system – when it comes to industrial manufacturing, we can answer today’s challenges and tomorrow’s desires.

By combining various components into a custom integrated drive system, we have successfully assisted countless companies in professionalizing their drive processes in recent decades.

Over the years, BEGE has increasingly focused on the innovation of customization at the component level. This means we select the best version of a specific component to fit perfectly within the machine. We cleverly combine and innovate existing technologies and deliver integrated technical customization to improve the drive process.

Curious about how we can help your company?

Make an appointment with our engineers.