ATEK bevel gear units

Efficient and powerful gear units for precise right-angle transmission.

ATEK bevel gear units

Bevel gear units are primarily used to convey motion at a 90° angle. Bevel gear units are mainly used to save space or for mounting a gear unit on a hollow shaft. Bevel gears are needed to achieve the most efficient right-angle solution. This type of gear has helical teeth, and the center lines of the gears intersect.

BEGE and ATEK bevel gear units

BEGE is an expert in bevel gear units, and we are an official distributor of the German ATEK brand of high quality, sturdy and reliable bevel gear units.

All gear units are made in Germany and sold both inside and outside Europe from our large stock in Sassenheim in the Netherlands.

ATEK’s bevel gear units are known for their very high efficiency thanks to the bevel gears, which transmit motion very precisely at a 90° degree angle. This results in an efficiency up to 98% and ensures quiet power transmission with less vibration.

Precision bevel gear units

ATEK bevel gear units have the following characteristic features:

- Highly accurate and powerful lightweight gear unit

- Efficiency up to 98%

- Helical gear sets

- Maintenance-free thanks to high-quality helical teeth

- Case hardened steel teeth

- Very favorable gear engagement for high loads

- Robust, powerful and compact design (V series)

- Small, lightweight and space-saving design (L series)

- Food-grade variant in stainless steel (HDV series)

- Corrosion resistant

- Low backlash design possible (to less than 4 arc-min)

Right-angle drive systems

ATEK offers a large variety of models and versions of bevel gear units. The wide product range of ATEK, combined with our application expertise, enables us to offer complete and optimized right-angle drive systems. This extends from designing custom gear units with attention to environmental and use factors to developing integrated right-angle drive systems tailored to customer requirements. We are happy to help you select the best right-angle transmission for your machine.

Supplier of ATEK bevel gear units

Powerful and precise bevel gear units for top performance and optimal axial and radial load capacity.

ATEK bevel gear units: the different ranges

Our product portfolio consists of 3 series bevel gear units of ATEK.

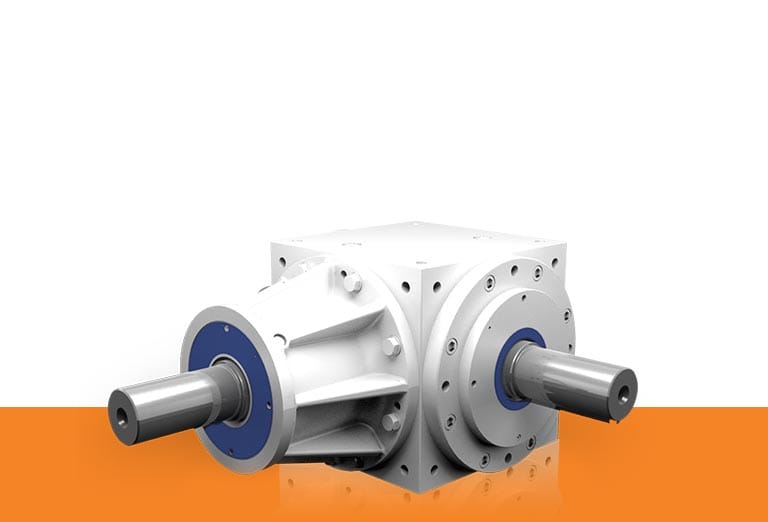

ATEK standard V series bevel gear units

Compact and shockproof.

Our V series standard bevel gear units are highly accurate and powerful torque converters. These high-quality gear units meet today’s high demands in every respect.

They are compact and insensitive to shock. For good reason, they are used worldwide in all industrial sectors of machine and mechanical engineering.

The V series covers gear ratios from 1:1 to 6:1 as well as intermediate gear ratios. They are also available in 1:1.5 or 1:2 overdrive.

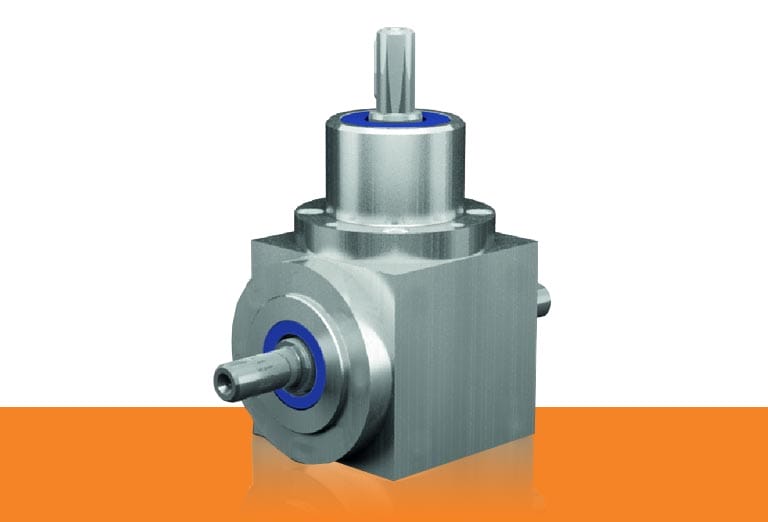

ATEK L series miniature bevel gear units

Space-saving aluminum gear units.

These miniature bevel gear units are specifically designed for use in small machines. ATEK mini bevel gear units are highly accurate and powerful lightweight units. They feature small size, high precision and space-saving design.

We offer these bevel gear units for applications in precision mechanical engineering, the medical sector, and precision robotics. They are available in four sizes with cubic dimensions of 35, 45, 65 and 85 mm and 1:1, 2:1, 3:1 and 4:1 gear ratios.

ATEK HDV series stainless steel bevel gear units

Bevel gear units with hygienic design.

This series of stainless steel gear units is based on the standard V series. The choice of materials, design and surface finish ensure optimal cleaning properties and maximum hygiene.

HDV bevel gear units are acid, alkali and corrosion resistant. This series features high efficiency, robustness and accuracy. This ensures a long and maintenance-free service life.

Ideal for food processing and pharmaceutical applications.

Our engineers have the specialist knowledge required to help you select the right bevel gear unit for your drive system. Feel free to contact us.

HOBA Case study

Our customer HOBA, a manufacturer of bread slicing, packaging and sealing machines, has been using ATEK bevel gear units for many years.

HOBA was wrestling with the implementation of their fully automatic Holly HSA-5 band slicer for different loaf sizes and came to BEGE for sound advice.

The case study describes how they use ATEK bevel gear units to position all the loaves correctly.

Advice & custom work

Our years of experience with drive technology also allow us to engineer innovative custom solutions that meet branche or customer-specific demands.

Whether it’s a small, compact machine or an extensive, complicated system; when it comes to industrial manufacturing, we can provide the answers to today’s challenges and tomorrow’s desires.

Sign up for BEGE news and updates