Case study

MdW Technical Support

Preventive gear motor replacement for a spiral freezer

As a knowledge partner, BEGE is involved in making the food industry more sustainable in terms of drive technology. This is reflected in the support we offer machine builders wishing to optimize their food production and processing machines. MdW Technical Support builds, maintains and installs complex machines for the food industry. Backed by more than 20 years of experience in the industry, they are experts in making machines efficient and safe.

Background & Assignment

MdW Technical Support asked BEGE Power Transmission to assist in the preventive replacement of the spiral freezer drive motor gearboxes at Oma Bobs. The drive motors of the cooling tower with double spiral and double belts had been around for some time when it was discovered that one of the gear units was nearing its end.

As the original supplier of the motors no longer existed, MdW turned to his drive partner BEGE for assistance to help him with the specifications of the motors and gear unit so that the drive would once again perform at its optimum level.

“I have been working with BEGE for 10 years and I am very pleased with the level of knowledge of all employees. In addition to the expertise and the fact that they are always involved, I am very pleased with their customer-friendly and solution-oriented way of working.”

Michel de Wit – owner of MdW Technical Support

Approach

Short research by MdW and the engineers of BEGE led to the recommendation to take immediate action. BEGE rewound the motors so that the machine could move forward again.

The risk of downtime had been eliminated for the time being, but it became clear that the gear motors in the cooling tower had to be replaced in the short term. In consultation with MdW, BEGE and Oma Bobs, they decided to completely renew the gear units at the beginning of 2019.

Working method

- Defining objectives

- Engineering services to optimize the entire construction

- Selection of appropriate drive components

- Prompt delivery of components from stock

- Close involvement in future projects

Result

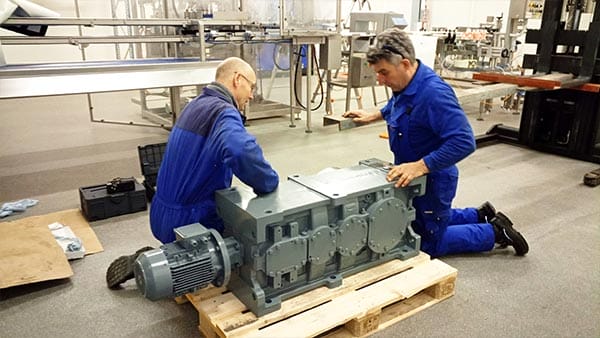

The result of the collaboration between Oma Bobs Snacks, MdW Technical Support and BEGE is the installation of a robust 700kg gearbox that is fully compatible with all relevant hygiene requirements and regulations. The gear motor is connected to a 2.2kW BEGE motor via a coupling flange. In combination with the enormous gearbox, the drive delivers a very high torque of 20,000 Nm at 0.9 rpm.

The summarized results:

- Fast implementation of a suitable solution aimed at the needs of the end customer

- The motors are IP56 and meet strict food safety requirements

- Upgrading the machine

- Support in the field of technology and calculations