Drives and controllers for agriculture & horticulture

Energy-efficient and cost-effective integrated drives and controllers for agricultural and horticultural applications.

Your experienced partner for the agricultural industry

BEGE supports machine builders, manufacturers and other players in this sector with optimal automation solutions. Our extensive knowledge of the industry enables us to always deliver a suitable drive or controller. As a knowledge partner, we are involved in making the food industry more sustainable in terms of drive technology.

It’s not about what we make, but about what we make possible.

Automation for agriculture and horticulture

Custom drives for the agricultural and horticultural industry

We develop and manufacture custom drives and automation solutions. Together with our customers in the agricultural and horticultural industry, we have already developed many tailored solutions. A number of applications are shown below. Move over an area to read more details.

Cutting flowers to varying lengths

Flowers & bulbs

Cutting flowers

Wish: Adjustable cutting unit for cutting flowers at variable lengths.

Solution: To streamline and accelerate flower cutting, a MIG encoder-controlled unit cuts flowers to the HMI setting length. A PLC-controlled conveyor with programmable speed delivers the flowers.

Operating egg transport system

Livestock & poultry farming

Operating egg transport system

Wish: Move eggs carefully and efficiently.

Solution: Egg trays transported to cart feed unit by a PLC-controlled vacuum conveyor that gently pushes trays into tray cart. Precise MIG encoder in cart feed drive for accurate positioning and minimal egg damage.

Controlling overhead trolley speed

Harvesting & crop care

Controlling overhead trolley speed

Wish: Control speed of overhead crop car to perform essential tasks.

Solution: User-friendly HMI control panel for two synchronized drive motors. Car automatically adjusts to speed of sowing or harvesting process.

Automatically de-rooting flower bulbs

Flowers & bulbs

De-rooting flower bulbs

Wish: Automatically remove roots in a peeler with adjustable pressure. Solution: A machine with HMI-adjustable stroke for optimal, clean results. PLC-controlled rollers turn in alternating directions to remove the roots.

Operating outdoor irrigation system

Harvesting & crop care

Operating outdoor irrigation system

Wish: Adjust flow rate of outdoor irrigation system.

Solution: Mechanical variator or electronic controller with HMI for easy manual adjustment even with muddy hands. No risk of (electronic) problems in irrigation process.

Dividing flower bulbs

Flowers & bulbs

Dividing flower bulbs

Wish: Automatically and carefully remove small bulbs from large bulbs. Solution: Two VFDs control belt speeds and speed difference to quickly and effectively separate large bulbs from small ones with minimal damage.

Efficiently drive manure robots

Livestock & poultry farming

Efficiently drive manure robots

Wish: Autonomous energy-efficient drive of manure robots.

Solution: Hypoid gear unit and attached DC motor with precise steering for navigation in the stable. Hypoid unit boosts manure robot efficiency, smaller battery pack sufficient.

Efficiently operate nest system

Livestock & poultry farming

Efficiently operate nest system

Wish: Encourage hens to leave the nest area in an animal- friendly way.

Solution: Timer-driven PLC-controlled expulsion system in automatic laying nests forces hens from nest at night. Quiet, efficient egg conveyor carries eggs to next processing step.

Driving and controlling mushroom picking bridge

Harvesting & crop care

Mushroom picking bridge

Wish: Automatic mushroom processing: sort; cut stems; pick, fill and weigh trays.

Solution: Automatic picking gantry continuously driven by efficient hypoid drives. Processes perfectly coordinated by PLC-controlled drives for optimal efficiency and speed.

PLC-controlled flower bulb harvesters

Flowers & bulbs

Flower bulb harvesters

Wish: Drive for bulb harvesters with optimum link to processing system. Solution: A custom VFD controller with PLC simultaneously controls switch systems, conveyors and curve belts to multiple machines and ensures optimum coordination.

Driving conveyor in seeder

Harvesting & crop care

Driving conveyor in seeder

Wish: Automatic pulp dosing from mix tank to sower seed trays.

Solution: Synchronized conveyor with encoder feedback moves seed trays automatically. PLC-controlled dosing unit on mix tank ensures correct amount preventing waste.

Automatic removal of cutting and bulb waste

Flowers & bulbs

Automatic waste disposal

Wish: Drive for automatic discharge of cutting and bulb waste.

Solution: A MIG encoder-controlled drive moves each full box so the next box can be placed and filled correctly. A simple PLC with encoder controls this system.

Controlling manure pushers

Livestock & poultry farming

Controlling manure pushers

Wish: Drive and control manure pushers in cowsheds.

Solution: Manure pusher controlled by electronic units with stepless traction protection and automatic start/stop. Manure pusher position determined by MIG feedback, even after a fault or power failure.

Controlling the speed of pipe rail cars

Harvesting & crop care

Controlling the speed of pipe rail cars

Wish: Adjust height and speed of tube rail cars in overhead crop care.

Solution: Height and speed easily and safely coordinated by PLC software. MIG encoder gives accurate feedback on car position and height and prevents unwanted acceleration.

Driving manure conveyor

Livestock & poultry farming

Driving manure conveyor

Wish: Faster manure drying with fully automatic manure conveyor.

Solution: Manure distributed evenly over different layers by synchronous conveyor drives. Elevator section with drum motor dumps manure into a container outside the stable.

Swipe ->

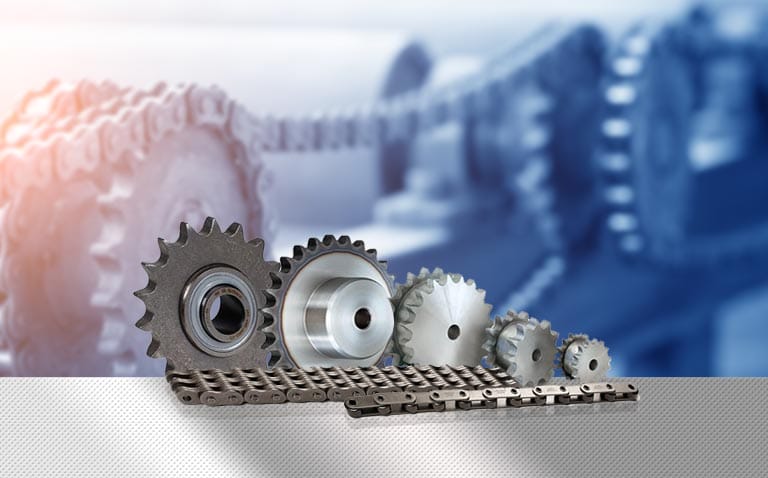

Drive components for the agricultural sector

Drive solutions for agriculture and horticulture

Our drive systems are highly suitable for tough performance in harsh conditions thanks to their high load capacity, long service life and high reliability.

Related topics and developments

Attractive products and comparisons for agricultural industry.

Want to know how our agricultural automation solutions can help you? Feel free to contact us.